- HOME

- PRODUCTS

- INDUSTRY

- ABOUT ICESTA

- VIDEO CENTER

- PROJECT&SOLUTION

- NEWS

- CONTACT US

IFSCV-15T

ICESTA

Ice Making System

| Availability: | |

|---|---|

| Quantity: | |

What is Sub-cooled Ice Making

1. Due to absence of condensation nuclei, water in liquid form at a Temp lower than 0 C is called Sub-cooled Water. Sub-cooled water, when under the influence of external stimulation (fast agitation, addition of other impurity particles, collision or ultrasonic stimulation), shall desist from its sub-cooling status and start internal heat exchanging, which causes some portion of sub cooled water to become tiny ice crystals.

2. Refrigeration Heat Exchanging Unit produces stable cooling capacity to generate sub-cooled water with our patented Technology. And the Crystallization System shall dissolve the sub-cooled status and allow the water to draw in the cooling capacity and change to ice slurry. Sub-cooled water is in the form of liquid when flowing through the heat exchanging unit, which is the best status for heat exchanging efficiency. Sub-cooled fresh water ice slurry making is the most effective and energy-friendly way for ice making globally.

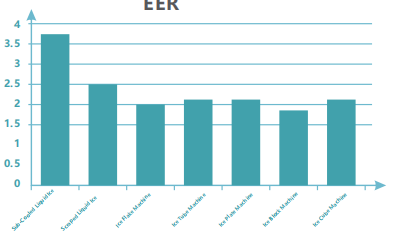

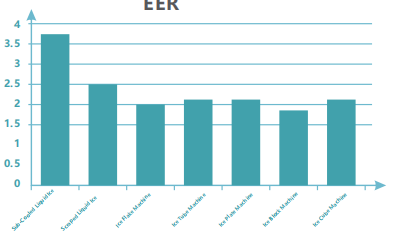

3. Sub-cooled ice making system uses refrigerant or refrigeration medium to making sub-cooled water, which operates at the evaporation temp of -3 to -5 degrees. This is the best ice making working conditions, compared to -15 to -30 degrees evaporation temp for traditional ice making ways. The maximum COP/EER that is reached by sub-cooled ice making system is invincible.

Working Principle

Details of A complete Sub cooled ice slurry

1. Ice Making units (A) continuously chill the water stored in Ice storage silo ( B) until the temp goes down to -2C under which circumstances slurry ice shall be generated on top of the Ice storage Silo ( B);

2. Ice storage Silo ( B) has an ice wiper assembly (C ) attached with a gearbox driven system, which throws ice down through the chute to the ice distribution devices ( D) or ( E) via centrifugal force. And dry ice delivered into ( D) or Slurry ice delivered into (E ) shall be delivered to different ice use points (F ).

3. Slurry ice Stirring unit (E ) shall deliver chilled slurry ice of different concentration ratios to various ice use points with a special screw pump.

Why Sub-cooled Slurry Ice System

1. Energy Saving

A. High Heat Exchange Efficiency Heat Exchanging happens between water and the cooling medium through plate exchanger with a temp difference of 0.5 Deg. That is an unparalleled feature of this ice maker.

B. High Evaporating Temp The Evap Temp shall be kept between -3 to -5 C, which is higher than any artificial ice making. That assures the system to work in a status of high COP, which is incomparable by all standards.

2. Efficient Fresh-Keeping

50μm ice crystals accumulate when the sub-cooled ice slurry is produced, which shall form soft and flowing ice bed. This type of ice slurry is ideal for fresh keeping as it can fill full any space left by the products. That will achieve incomparable coolness to that of solid ice.

3. Well-suited Storage & Application

The fluidity of ice slurry makes its storage and application convenient and laborless. The storage facility can be a stand-alone & insulated fiberglass silo, which features a confined foot print. Silos are well structured for automatic applications: dry ice slurry can be wiped down from top and mixed with cold water and pumped to different ice use points at desired ice concentration. While solid ice can be more troubling for transportation.

Applications

1. Thermal Storage in AC and other Fields

The thermal storage procedure is realized by ice slurry in the form of latent heat. The energy storage density in the storage tank shall be 12RTh/m3. The refrigeration unit shall work at hours of lowly priced electricity and energy stored this way shall be used at hours of highly priced electricity in an attempt to save energy cost.

What is Sub-cooled Ice Making

1. Due to absence of condensation nuclei, water in liquid form at a Temp lower than 0 C is called Sub-cooled Water. Sub-cooled water, when under the influence of external stimulation (fast agitation, addition of other impurity particles, collision or ultrasonic stimulation), shall desist from its sub-cooling status and start internal heat exchanging, which causes some portion of sub cooled water to become tiny ice crystals.

2. Refrigeration Heat Exchanging Unit produces stable cooling capacity to generate sub-cooled water with our patented Technology. And the Crystallization System shall dissolve the sub-cooled status and allow the water to draw in the cooling capacity and change to ice slurry. Sub-cooled water is in the form of liquid when flowing through the heat exchanging unit, which is the best status for heat exchanging efficiency. Sub-cooled fresh water ice slurry making is the most effective and energy-friendly way for ice making globally.

3. Sub-cooled ice making system uses refrigerant or refrigeration medium to making sub-cooled water, which operates at the evaporation temp of -3 to -5 degrees. This is the best ice making working conditions, compared to -15 to -30 degrees evaporation temp for traditional ice making ways. The maximum COP/EER that is reached by sub-cooled ice making system is invincible.

Working Principle

Details of A complete Sub cooled ice slurry

1. Ice Making units (A) continuously chill the water stored in Ice storage silo ( B) until the temp goes down to -2C under which circumstances slurry ice shall be generated on top of the Ice storage Silo ( B);

2. Ice storage Silo ( B) has an ice wiper assembly (C ) attached with a gearbox driven system, which throws ice down through the chute to the ice distribution devices ( D) or ( E) via centrifugal force. And dry ice delivered into ( D) or Slurry ice delivered into (E ) shall be delivered to different ice use points (F ).

3. Slurry ice Stirring unit (E ) shall deliver chilled slurry ice of different concentration ratios to various ice use points with a special screw pump.

Why Sub-cooled Slurry Ice System

1. Energy Saving

A. High Heat Exchange Efficiency Heat Exchanging happens between water and the cooling medium through plate exchanger with a temp difference of 0.5 Deg. That is an unparalleled feature of this ice maker.

B. High Evaporating Temp The Evap Temp shall be kept between -3 to -5 C, which is higher than any artificial ice making. That assures the system to work in a status of high COP, which is incomparable by all standards.

2. Efficient Fresh-Keeping

50μm ice crystals accumulate when the sub-cooled ice slurry is produced, which shall form soft and flowing ice bed. This type of ice slurry is ideal for fresh keeping as it can fill full any space left by the products. That will achieve incomparable coolness to that of solid ice.

3. Well-suited Storage & Application

The fluidity of ice slurry makes its storage and application convenient and laborless. The storage facility can be a stand-alone & insulated fiberglass silo, which features a confined foot print. Silos are well structured for automatic applications: dry ice slurry can be wiped down from top and mixed with cold water and pumped to different ice use points at desired ice concentration. While solid ice can be more troubling for transportation.

Applications

1. Thermal Storage in AC and other Fields

The thermal storage procedure is realized by ice slurry in the form of latent heat. The energy storage density in the storage tank shall be 12RTh/m3. The refrigeration unit shall work at hours of lowly priced electricity and energy stored this way shall be used at hours of highly priced electricity in an attempt to save energy cost.

+86 13510956930

Yangchong Industry Zone, Shapu Songgang,Baoan District.Shenzhen.China

SHENZHEN BROTHER ICE SYSTEM CO.,LTD © 2021 - ALL RIGHTS RESERVED SUPPORT BY LEADONG SITEMAP PRIVACY POLICY